User blogs

Mobile phone is no longer a rare thing, and now people in daily life essential personal items, instant messaging, camera, use the APP, play games and even pay for the purchase, all inseparable from smart phones. A small cell phone, even with so many features, it makes people have to wonder! And you know, green laser pointer as an advanced processing technology, in the mobile phone manufacturing process, played a pivotal role.

Laser marking is the use of high-energy laser irradiation of the workpiece on the local exposure, the surface material vaporization or color change of the chemical reaction, leaving a permanent mark of a marking method, with high precision, fast, clear mark And so on. Mobile phone laser marking this permanent marking method, can improve the anti-counterfeiting ability, but also increase the added value, the product looks higher grade, more brand. In the phone we can find the shadow of laser marking, such as: Logo marking, cell phone keys, cell phone casing, cell phone batteries, mobile phone accessories, marking, etc., even in your invisible cell phone, there are parts laser pointer .

Laser cutting can be metal or non-metallic parts and other small parts for precision cutting or micro-hole processing, cutting with high accuracy, speed, heat and other advantages. Mobile phone common laser cutting technology: sapphire glass mobile phone screen laser cutting, lens protection lens laser cutting, mobile phone Home key laser cutting, FPC flexible circuit board laser cutting, mobile phone handset network laser drilling and so on.

Laser welding is the use of high-energy laser beam as a heat source, the material surface melting and then solidified into a whole. Heat affected zone size, weld aesthetics, welding efficiency, is an important indicator of good or bad welding process. HG laser precision burning laser pointer welding machine for the processing of parts, precision instruments and other small parts, high precision welding, integrated, split and other welding supporting the choice of workstations.

Today, LDS laser direct molding technology has been widely used in the manufacture of smart phones, the advantage is that the use of laser direct molding technology marked on the phone shell antenna trajectory, whether it is a straight line, curve, as long as the laser can place, Can create 3D effects, to maximize the savings of mobile space, and can adjust the antenna trajectory at any time. As a result, the phone will be able to do more thin, more refined, stability and shock resistance is also stronger.

Personal electronic equipment, represented by mobile phones, is greatly changing and facilitating people's lives. Functionalization, intelligence, and smartness are the development direction of mobile phones. With the micro-electronics industry, technological progress and the pursuit of personalized mobile phone, fine 400mw laser pointer processing technology in mobile phone manufacturing play an increasingly important role. At the same time, the laser is also promoting the development of other microelectronics manufacturing-related industries.

http://laserman123.parsiblog.com/Posts/1/Process+Analysis+of+Laser+Welding/

http://www.elosinternacional.org/blogs/view/728/process-analysis-of-laser-welding

Over the past decade, the so-called single-layer materials by scientists attach great importance to these materials in the field of physics has a very large potential. At the beginning of 2016, the research team of the University of Würzburg was supported by the European Research Council (ERC) 15 million euros for the study of transition metal sulfides (TMDC). Some progress has been made.

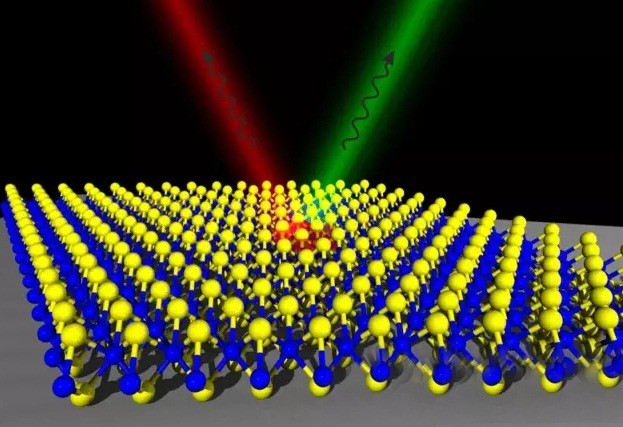

In physics, a & quot; monolayer & quot; refers to a minimum thickness of a solid material, typically a single atomic layer thickness, and the crystalline material may be three or more blue laser pointer of atoms, also referred to as two-dimensional materials. Two-dimensional materials often exhibit unexpected properties. Such as TMDC, have similar characteristics of the semiconductor can be used to manufacture ultra-small, energy-efficient chip. TMDC has a fairly simple two-dimensional structure. Molybdenum or tungsten and other transition metal atoms in a single row structure, caught in the same thin layer of sulfur between the elements. TMDC made with different base components has a wide range of electronic and optical properties.

The team at the University of Würzburg, Germany, found that TMDC can emit light when it absorbs energy. Experiments show that this new single-layer material can be used in the manufacture of new energy efficient laser source can also be used for quantum effects research.

Quantum Communications Research: First, a single layer of material is prepared by a simple method. In the first step, the multilayer film is peeled off from the TMDC crystal with tape. A thinner film is peeled off from the multilayer film, and is repeated to obtain a single-layer material. The monolayer material is then cooled to a temperature slightly above absolute zero and excited with a 3000mw laser pointer, under which the single layer of material will emit a single photon. The researchers explained that, in fact, the excitation of two photons, light particles are produced in pairs. This photon is very interesting to the source: the photon pairs of two photon states overlap each other, entangled together. The state of one photon directly affects the other photon, and is not limited by distance, a principle that can be used to encrypt communications.

For new laser sources: Scientists at the University of Würzburg have demonstrated another application of this monolayer material. A single layer of material is placed between the two mirrors and then excited with a laser. When the laser radiation reaches a certain degree, TMDC starts to emit photons. These photons hit the mirror and send color back to the TMDC plate, which stimulates TMDC atoms to produce new photons. "We call this process a strong coupling, and the action of light and matter produces exciton-polarized photons." This is the first time that polarized photons have been detected at room temperature in monatomic layers. This "clone" photon has similar properties to 400mw laser pointer, but produces a fundamentally different principle. Ideally, after the initial excitation, new light particles can be generated by self-sufficiency, without any additional energy supply. In contrast, the laser material in the laser requires external sustained excitation.

http://laserman123.canalblog.com/archives/2016/11/08/34539740.html

http://faceluck.org/blogs/post/5908#sthash.5sempsXl.BdXjlo8t.dpbs

http://laserman123.jigsy.com/entries/general/analysis-of-the-principle-of-laser-fire-alarm-system